Good day to all,

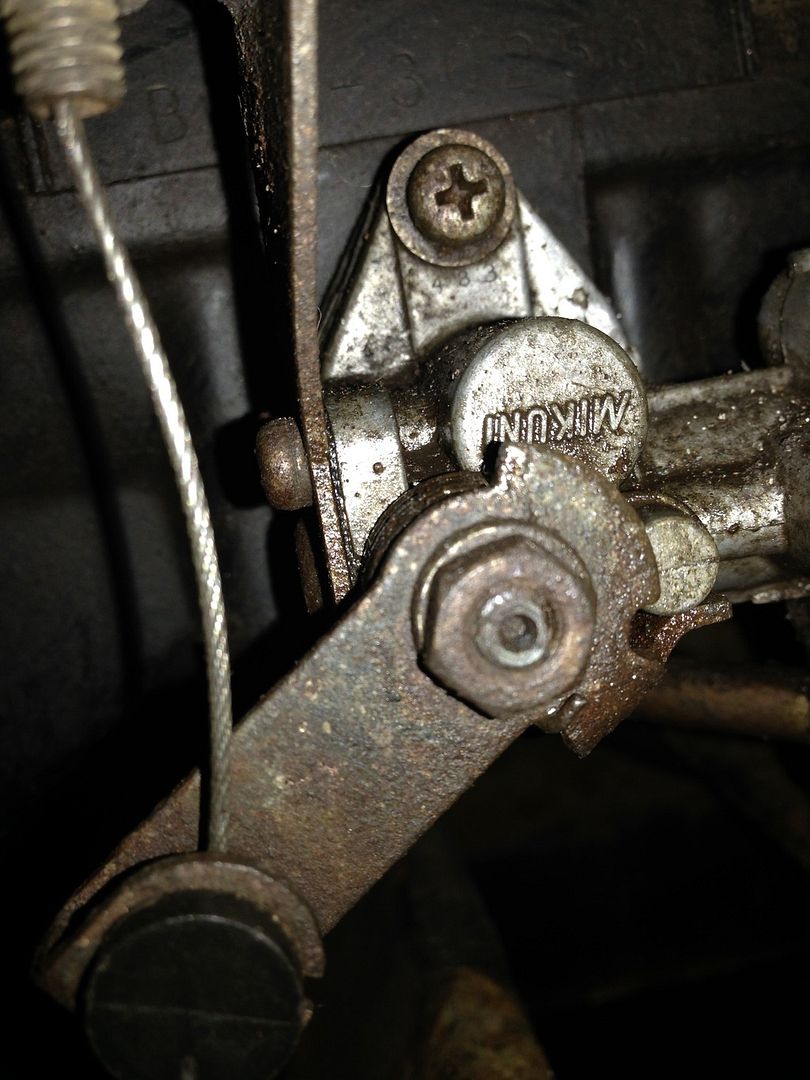

Its been close to 3 years since I resurrected a sled that was given to me for free.... a 1994 EXT 580 EFI (that got converted to CARB with a ZR hood)

Back then, I simply got it running, got the basics like drive belt and fixed the wiring after the sled was sitting outdoors for 9 years.

I figured lets see how long it lasts and every day is a bonus.

Since then my dad has been using it every winter for his ice fishing trips, towing a little sled and using it with a passenger almost every weekend... 3 seasons in! All we had to do is replace the drive belt again and rear shocks.

This time around, decided its time for a top end as even 3 years ago I saw scratch marks on the pistons through the exhaust ports.

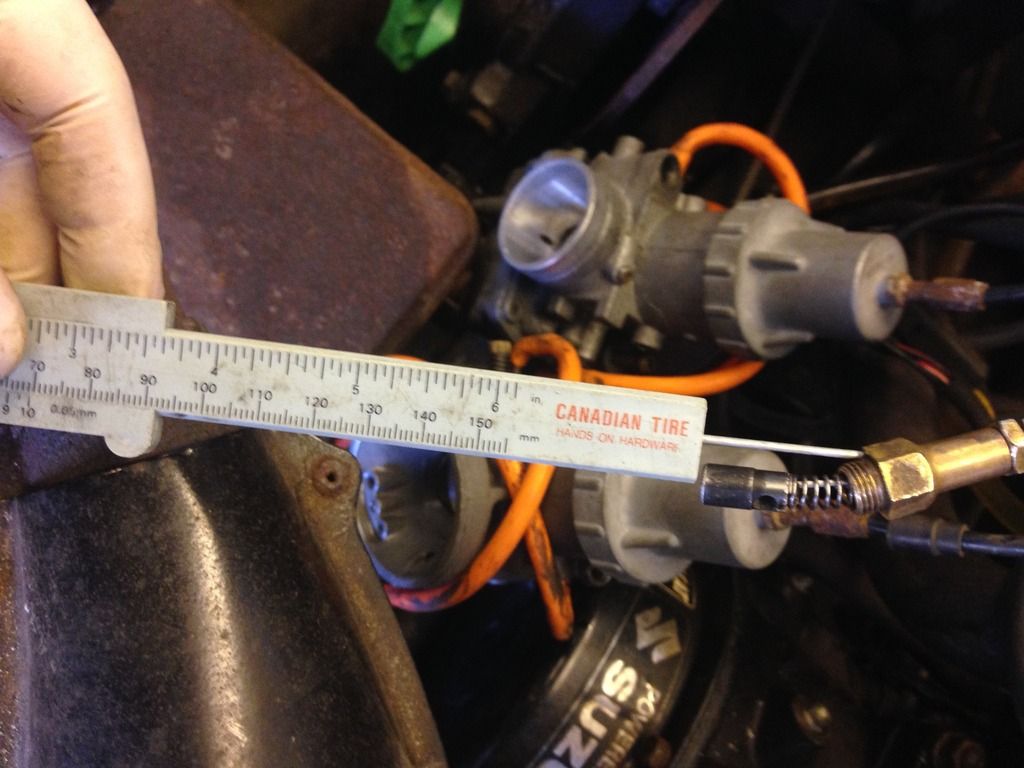

So he we go..... The engine is out, cylinders are off for cleaning and Im about to order the SPI pistons/rings/bearing/gasket kit for the top end.

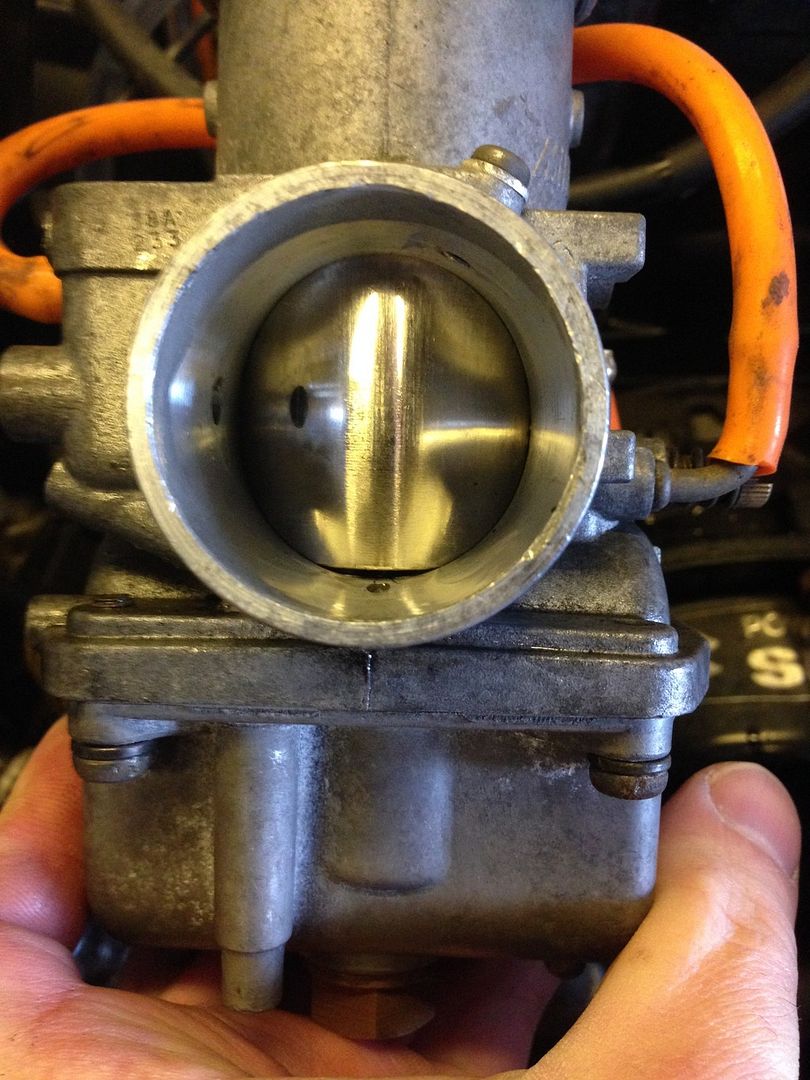

The good news is that the scuffs on the pistons are not too bad, there is no dings or real bad scratches on the cylinder walls either.

What I need help with, is reminding me how to check for signs of bottom end problems and to find out if I need to split the bottom (never done it) and to replace the bearings on the crankshaft (anything else there wears out?)

The sled will nee an overall cleaning and touch ups... which I will proceed with based on the health of the engine and bottom end.

Your help and advice is appreciated. (never done a snowmobile rebuild, just a few top end on dirt bikes)

Thanks in advance.Cat happy

Its been close to 3 years since I resurrected a sled that was given to me for free.... a 1994 EXT 580 EFI (that got converted to CARB with a ZR hood)

Back then, I simply got it running, got the basics like drive belt and fixed the wiring after the sled was sitting outdoors for 9 years.

I figured lets see how long it lasts and every day is a bonus.

Since then my dad has been using it every winter for his ice fishing trips, towing a little sled and using it with a passenger almost every weekend... 3 seasons in! All we had to do is replace the drive belt again and rear shocks.

This time around, decided its time for a top end as even 3 years ago I saw scratch marks on the pistons through the exhaust ports.

So he we go..... The engine is out, cylinders are off for cleaning and Im about to order the SPI pistons/rings/bearing/gasket kit for the top end.

The good news is that the scuffs on the pistons are not too bad, there is no dings or real bad scratches on the cylinder walls either.

What I need help with, is reminding me how to check for signs of bottom end problems and to find out if I need to split the bottom (never done it) and to replace the bearings on the crankshaft (anything else there wears out?)

The sled will nee an overall cleaning and touch ups... which I will proceed with based on the health of the engine and bottom end.

Your help and advice is appreciated. (never done a snowmobile rebuild, just a few top end on dirt bikes)

Thanks in advance.Cat happy